Navigating The World Of Lubricants: Classification of Lubricants

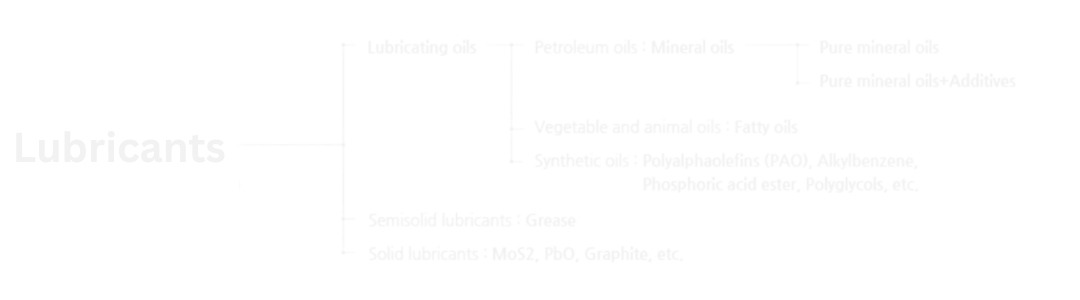

Lubricants help to decrease friction and wear between moving components in a variety of equipment and industrial processes. They are critical to the efficiency, dependability, and lifespan of mechanical systems. Lubricants may be classified based on various factors, such as their composition, physical qualities, and uses.

In this article, which continues our “Navigating The World Of Lubricants” series on raising awareness of the sector, we discuss lubricants which are classified on the basis of their physical state.

Lubricating oils

Lubricating oils also known as liquid lubricants and further classified into three categories:

(1) Animal and Vegetables oils

(2) Mineral or Petroleum oils and

(3) Blended oils

Characteristics of good lubricating oils include:

(1) High boiling point

(2) Low freezing point

(3) Adequate viscosity for proper functioning in service

(4) High resistance to oxidation and heat

(5) Non-corrosive properties

(6) Stability to decomposition at the operating temperatures

Animal and Vegetables oils: Animal oils are made from crude fat and vegetable oils like cottonseed oil and caster oils. Due to their composition they adhere to metal surfaces effectively even at high temperatures and stresses.

However, they have the disadvantages of being a higher price, quickly oxidised to produce sticky products, and easily hydrolyze when exposed to wet air or water. As a result, they are only infrequently utilised for lubrication these days. They are, however, still employed as blending ingredients in petroleum-based lubricants to improve oiliness.

Mineral or Petroleum oils: These are low molecular weight hydrocarbons containing 12 to 50 carbon atoms. They are frequently utilised because they are inexpensive, plentiful, and stable under service conditions. However, because mineral oils have a lower oiliness, the addition of larger molecular weight molecules such as oleic acid and stearic acid increases the oiliness of mineral oil.

Blended oils: Because no single oil possesses all of the qualities required for a good lubricant, the addition of appropriate additives is required to make them operate well. Blended oils are lubricating oils that have additives added to them.

Examples: The addition of higher molecular weight compounds like oleic acid, stearic acid, palmetic acid, etc or vegetable oil like coconut oil, castor oil, etc increases the oiliness of mineral oil.

Semi-solid Lubricants or Grease

Grease is a semi-solid lubricant made by blending lubricating oil and thickening additives. The main component is lubricating oil, which can be either petroleum oil or synthetic hydrocarbon with a low to high viscosity.

Grease can withstand significantly larger loads at slower speeds. Because the internal resistance of grease is much higher than that of lubricating oils, it is preferable to use oil instead of grease.

Grease, unlike lubricating oils, cannot properly remove heat from bearings and must thus perform at lower temperatures.

Solid lubricants

Solid lubricants are preferable when:

(1) The working conditions prevent the formation of a lubricating layer when lubricating oils or grease are used

(2) Contamination of lubricating oils or grease (due to dust particle penetration) is unacceptable

(3) The operating temperature or load is too high, even for grease to remain in position; and

(4) Flammable lubricants must be avoided

Solid lubricants are utilised in either dry powder form or with binders to ensure that they adhere firmly to metal surfaces while in use. They are accessible as dispersions in nonvolatile carriers such as soaps, fats, waxes, and so on, as well as soft metal films.

Graphite, molybdenum disulphide, tungsten disulphide, and zinc oxide are the most frequent solid lubricants. They can resist temperatures of up to 650° C and can be used in continuous operation. They are also used as additives to mineral oils and greases to boost the lubricant’s load-carrying ability. Soapstone (talc) and mica are two more solid lubricants in use.

Graphite is the most commonly used solid lubricant, and it can be used in powdered or solution form. It has a soapy feel to it, is non-flammable, and is stable up to 375° C.

Graphite has a flat plate-like structure, with layers of graphite sheets stacked one on top of the other and held together by weak Vander Waal’s forces.

Graphite is an efficient lubricant due to its parallel layers that can readily slide one over the other. In addition, the graphite layer has a proclivity to absorb oil and become saturated with it.

Molybdenum disulphide is a sandwich-like compound containing a layer of molybdenum atoms sandwiched between two layers of sulphur atoms. The lack of inter-laminar interaction allows these layers to readily slide over one another. It is temperature stable up to 400° C.

Source:

- https://yanthrist.com/different-types-of-lubricants-properties-application/

- https://onlinelibrary.wiley.com/doi/10.1002/9781118907948.ch2

- https://prog.lmu.edu.ng/colleges_CMS/document/books/MCE321%20-%20Lubrication%20and%20Lubricants.pdf