The Unsung Heroes: Exploring the Crucial Role of Lubricants Across Diverse Industries

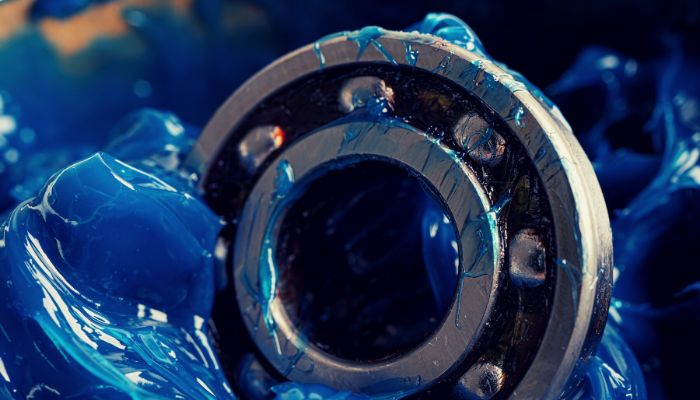

Lubricants are often overlooked in the grand scheme of industrial processes. However, lubricants play a critical role in the smooth operation and longevity of machinery and equipment in a wide range of industries.

These unassuming substances serve as the lifeblood of manufacturing plants, automotive industries, aviation, marine, and even healthcare, ensuring the efficient operation of machinery and minimising wear and tear. In fact, anything that moves and creates friction — you will find a need for Lubes and Greases.

In our 4th part of the “Navigating the World of Lubricants” article series, we explore industries where lubricants play an important role, contributing significantly to their smooth operation.

Manufacturing

The importance of lubricants in the manufacturing sector, where heavy machinery is widely used, cannot be overstated. Lubricants are a barrier, reducing friction between moving parts and preventing excessive wear and tear. Lubricants facilitate smooth movement by forming a film between surfaces, reducing friction-generated heat, and preventing machinery breakdowns. This translates directly into increased operational efficiency, decreased downtime, and extended equipment lifespan, ultimately lowering maintenance costs.

Automotive and Transportation

Lubricants are the unsung heroes of the automotive industry, ensuring the optimal performance of engines and vehicle components. Engine oils, gearbox fluids and greases all work together to reduce friction, dissipate heat and prevent corrosion of critical components. They allow engines to run at peak efficiency while also extending the life of critical parts like pistons, bearings, and gears. With the continuous advancement of automotive technology, the demand for specialised lubricants to meet the specific requirements of modern engines has increased, resulting in advanced formulations for improved performance and fuel efficiency.

Aerospace and Marine Industries

Lubricants are critical to the aerospace and marine industries. Operating in intricate machinery and systems. Specialised lubricants are required for nose-to-tail in aviation, particularly in aircraft engines, landing gear, and turbines. Also, in marine propulsion systems, where safety and precision are paramount. These high-performance lubricants can withstand extreme temperatures and pressures, ensuring smooth operations and preventing catastrophic failures that could jeopardise safety.

Wind Power Sector

Lubricants in wind turbines are the lifeline of these massive structures, preserving the functionality of gears, bearings, and hydraulic systems. Wind turbines require specialised lubricants that can withstand extreme temperatures and pressures, ensuring continuous operation and preventing downtime.

Electricity & Power Generation Sector

With its array of turbines, generators, and transformers, the power generation sector heavily relies on lubricants to ensure uninterrupted electricity production. These lubricants protect critical components from friction-induced wear and corrosion, allowing machinery to run efficiently for extended periods. Furthermore, specialised oils and greases are developed to meet the specific needs of high-voltage equipment, ensuring operational reliability and safety.

Health and Food Industries

Lubricants play an important role in seemingly unrelated industries such as healthcare and food production. Specialised lubricants in medical devices, pharmaceutical manufacturing, and food processing equipment ensure strict regulatory compliance while maintaining cleanliness and preventing contamination. These lubricants are frequently designed to be food-grade or medical-grade, ensuring the utmost safety and purity.

Environmental Impact

Furthermore, the lubricant used has an impact on the environment. With a greater emphasis on sustainability, industries are shifting towards bio-based and environmentally friendly lubricants. These greener alternatives not only reduce the carbon footprint but also provide comparable performance and longevity, aligning with the global push for greener practices.

Next: Surprising Sectors Where Lubricants Make a Difference